Wine Grape Analysis from Daniel Pambianchi

The article below was written by Daniel Pambianchi who is the author of the best selling book, Techniques in Home Winemaking. He also created and moderates the largest (and best) Home Winemaking Group on Facebook. You can hear him speak live this summer at one of his seminars on Consistently Making Flawless Wines.

My Quest for Top-Quality Fruit for Making Superlative Wines

By Daniel Pambianchi – April 28th, 2019

So I’m on a quest to make, not great, but superb wines from top-notch fruit (i.e., grapes). And therein lies my challenge . . . every year – sourcing top-notch fruit, juice or must (juice with grape skins).

I live in Montreal (Quebec, Canada) where purveyors of fruit and juice for winemaking cater predominantly to the older generation of cost-conscious winemakers and to those wanting to make tiny batches of good, early drinking wine (inexpensively too). I have resorted to driving hours and hours or paying premium dollars to get juice or frozen must that I can turn into superlative wines, wines with a bang of a wow factor. It hasn’t been easy, but wholesalers and distributors are catching up and now sourcing grapes from not only California’s Central Valley, but also from Oregon and Washington in northwestern US, as well as the Southern Hemisphere from Chile and Argentina and as far as South Africa to satisfy the needs of discriminating amateur winemakers.

WineGrapesDirect.com

WineGrapesDirect, operated by partners Andrew and Mikey Crews, is one such purveyor of high-quality juice and must from grapes sourced from premium vineyards in California, Oregon, and Washington. Crushed must (reds) and pressed juice (whites) are flash-frozen and then shipped by courier anywhere throughout the continental US and Canada.

I have become partial to frozen must because the freezing process ruptures grape cell walls and release more anthocyanins (color pigment molecules) and increase color extraction. It had always been a challenge extracting color in the okay grapes from the Central Valley I was able to source locally.

So I decided I would try three 5-gallon (20-liter) pails of WineGrapesDirect’s best of the best for evaluation purposes, and since I live a short one-hour drive from the US border and there is no duty or taxes on (unfermented) frozen must, I had the pails shipped to a pick-up location just across our friendly border.

I chose the following varieties, one white and two reds, from the 2018 harvest (prices are in US$ for 5-gal pails unless stated otherwise):

Since these are tiny batches for evaluation purposes, the wines will not be aged in oak barrels, but they will be given the full and maximum-extraction treatment to turn these into very full-bodied, dry wines with long aging potential. By “dry,” I mean to have less than 2 g/L of residual sugar (RS) in the finished wines, and so, acidity cannot be too high so as not to throw off balance. And in lieu of barrel aging, I will use WineStix, an oak-barrel alternative with which I have had excellent success in the past.

Some Numbers on the Juice and Musts

Once the pails thawed and were in working temperature range, around 10°C (50°F), I analyzed juice samples thoroughly in my lab to assess, for example, acidity, pH, nitrogen levels, and color to determine what adjustments, if any, would be required before initiating alcoholic fermentation (AF).

Before presenting the analysis, some parameters are worth explaining.

PA, or Potential alcohol, expressed in % alcohol by volume, is calculated from Brix readings according to the following equation:

There are many variations of calculations for this conversion, but over the years, I have found that this calculation is closest to the actual amount of alcohol measured in the wine after alcoholic fermentation (AF) is done.

Since high-pH grapes, juice or musts have been a perennial problem in my winemaking, I now regularly measure the amount of potassium ions (K+), the most significant factor influencing pH and tartrate stability. High pH also reduces color and color stability in reds due to a shift of anthocyanins to the non-colored forms. It’s very hard to deal with high K+ in juice in home winemaking, but the measurement will provide some clues as to the extent of any potential issues.

FSO2 and TSO2 are a measure of free and total sulfur dioxide (SO2), respectively. These will be more important during post-fermentation processing; I measured these parameters in the juice/musts to see if any sulfite was added to the juice and to determine how much, if any, I would have to add to keep indigenous yeast and chemical oxidation in check while ensuring not to add too much, which could otherwise inhibit bacteria for the malolactic fermentation (MLF). All three wines will undergo MLF, and I am planning to inoculate for MLF soon after the start of the AF.

YAN, or Yeast Assimilable Nitrogen, is a measure of the amount of nitrogen that yeast cells can assimilate and use for their metabolic functions during AF. A short or even an over-supply of nitrogen can cause fermentation problems and possibly lead to flaws or faults, the dreaded, stinky, rotten-egg smell of hydrogen sulfide (H2S) being the most common. The amount of YAN yeast needs depends on Brix; typically, at 21, 23, and 25 Brix, yeast needs 200, 250, and 300 mg YAN/L, respectively.

Turbidity, measured in Nephelometric Turbidity Units, is measured in white juice to identify potential fermentation problems, such as the production of volatile sulfur compounds (H2S is one such substance). The maintenance of a sufficiently high level of turbidity is essential for white wine production, with solid particles acting as a source of lipids for yeast growth under anaerobiosis (absence of air). The recommended range is 100–250 NTU though some research indicates that levels as low as 50 NTU are sufficient.

DO, or Dissolved Oxygen, is a measure of the amount of oxygen already present in juice. DO is normally tracked post-fermentation in wine to monitor any potential oxidation issues. I measured it here, in conjunction with A420, to assess the state of the juice/musts and to identify any potential storage issues of the frozen juice/musts. A420 is a measurement of the absorbance measured at a wavelength of 420 nm; it gives an indication of the amount of yellow color in white juice and it if is turning to a brown color.

In reds, A420 is also used to assess the extent of chemical oxidation and if color is taking on orangey or brownish hues. A similar measurement is made at 520 nm for A520 to determine the amount of red color and to calculate Color Intensity, or IC. Full-bodied reds, the style I am aiming for, have IC values in the range 8–12. Another similar measurement is made at 620 nm for A620 to determine the amount of blue color (a characteristic in young wines) and to calculate a modified IC. Since the red-color aspect is not obvious from these parameters, another parameter, brilliance of red, is calculated from the absorbance readings, and the higher the percentage, the greater the brilliance.

Hue is the ratio of absorbance measurements at 420 nm and 520 nm, i.e., the amount of yellow color to red color, and gives an indication of aging and possibly premature oxidation. Young reds, before there is any oxidation, should have a hue of less than 0.8, i.e., the yellow component should never dominate.

Missing from this analysis is the polyphenol status in reds; total phenols (TP) is measured post-fermentation as tannins are first extracted from grape skins and, to some extent, seeds, during fermentation. TP along with A280 measurements will provide useful data on full-bodiedness, astringency, bitterness, and aging potential.

Following are the numbers I measured for the three lots, and my maceration–fermentation strategies.

2018 Russian River Chardonnay, Olivet Lane Vineyard

The numbers look pretty good, though some attention is required, particularly that I intend to put this wine through MLF.

Total Acidity (TA) will increase as succinic acid is produced during the AF, although the low tartaric acid component of TA indicates that there is likely high malic acid, which will be converted into lactic acid during MLF and decrease the overall TA to possibly a very low level. (I am not yet equipped to measure reliably the amount of malic acid in juice or wine.) I’m also not expecting much change in TA during cold stabilization due to the low tartaric and K+ contents. So I won’t make any acidity adjustments at this stage; I will re-evaluate post AF/MLF and make any necessary adjustments.

Given that DO is close to saturation (about 8 mg/L at 20°C/68°F and 1 atm) and that there is less than 7 mg/L of free SO2 from the 40 mg/L added at the freezing stage, I want to avoid any possible premature oxidation and bump that up a little to keep the oxygen in check, and so I added 25 mg/L of SO2. The color was a light golden; I measured A420 here so that I have a reference point to identify any potential oxidation problems later on. I also added some OptiMUM White, which contains GSH, or glutathione, a strong antioxidant. GSH is naturally occurring in grapes but I suspect that it may have been entirely consumed in the juice here during processing and storage.

YAN is a bit high but still very good for this Brix level, so there are no nutritional issues to worry about here.

The relatively low NTU just means that the juice cleared itself quite a bit during processing and storage. I’m not really concerned at this point having worked with low NTU juices many times previously.

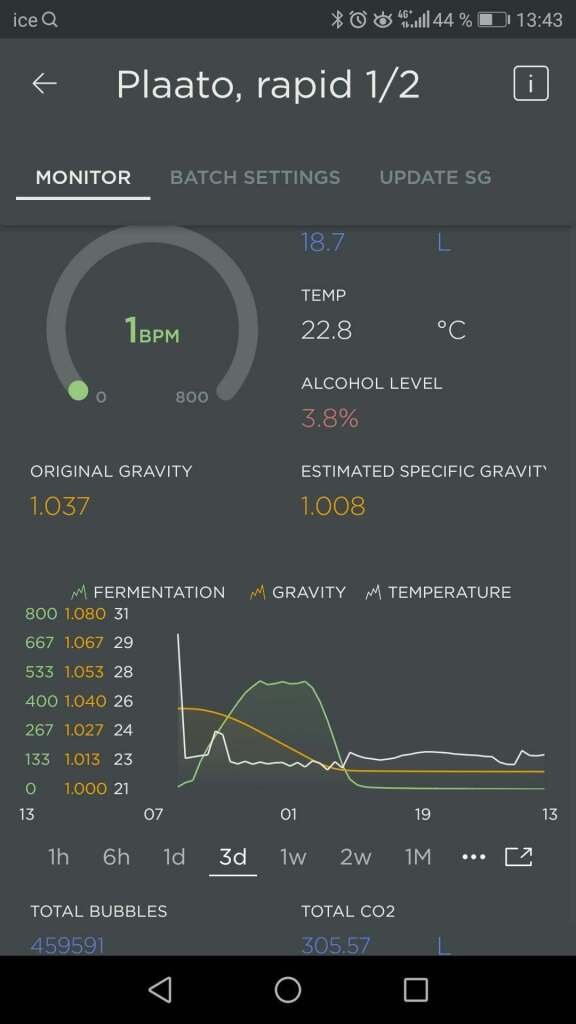

My choice of yeast for this wine is Lalvin Bourgoblanc CY3079, which is recommended specifically for rich, full-bodied Chardonnay and sur-lie aging. I’ll use some yeast rehydration nutrients (Go-Ferm) and additional nutrients (Fermaid K) at one-third Brix depletion for a smooth fermentation. To monitor fermentation progress, I will use a Plaato, a new Wi-Fi-enabled airlock that measures SG and sugar conversion by counting the number of carbon dioxide (CO2) bubbles produced per minute based on the juice volume and Specific Gravity (SG) entered at the start of the batch.

For the MLF, I have chosen Lactoenos B7 (LF16) Direct inoculum; I have had great success with this bacterium. I will inoculate shortly after the AF has started to get the MLF to complete at the same time as the AF or shortly thereafter.

Click here to learn more about Lallemand winemaking products and click here for Laffort’s products.

2018 Napa Valley Cabernet Sauvignon, Calistoga AVA

Looking at these numbers, the first thing that jumps out is the high pH; this is largely due in part to the high K+ content (compare these numbers to those for the Pinot Noir below). The most important issue needing attention is protecting the must and resulting wine against microbial spoilage (microbes thrive at higher pH) and premature chemical oxidation. Here I added the equivalent of approximately 50 mg/L of SO2. Frequent punchdowns during maceration and fermentation should be sufficient to keep things in check for now, but higher doses of sulfite will be required post-AF/MLF to protect the wine during aging. As I’m expecting TA to increase during the AF, the pH will drop, but that will be offset by an increase in pH if I decide to cold stabilize the wine and drop the K+ level. I’ll re-evaluate this post-AF/MLF.

YAN should be around the 250 mg/L for this Brix level, so I will make up the difference by adding a diammonium phosphate (DAP) formulation (Thiazote PH).

Let’s take a look at SO2 numbers now along with DO and color parameters to understand the status of the must and what happened during its storage.

No sulfite was added to the must prior to flash freezing. DO is very, very low (40 µg/L), and that’s good if we compare this to the DO of 7.50 mg/L for the Chardonnay. What happened here in the Cab is that polyphenols went to work and did their job in protecting against chemical oxidation in the absence of SO2. There are no visible signs of oxidation by inspecting the color; however, a spectrophotometric analysis reveals a slightly high yellow component relative to the red component with the hue calculated to be 1.21 – this should be less than 0.8 at this stage. The approximately 50 mg/L of SO2 added should “remove” some of that yellow color and restore the red color and increase it brilliance, which is low (14.7%) at this stage. I also need to keep in mind that the high pH reduces color and color stability. This means that I will need to focus on extracting as much color as possible during maceration via appropriate and timely additions of color-extracting enzymes (HE Grand Cru) and fermentation tannins (Tanin VR Supra). I will also be adding some inactivated yeast derivative nutrients (Opti-Red) to help this process and then stabilize color when it reaches its peak by adding another dose of Tanin VR Supra. All this with frequent punchdowns should get the IC in the desired 8–12 range and red brilliance well above 60%.

My choice of yeast for this wine is Uvaferm BDX, which is recommended for rich, full-bodied red varietals and specifically for Bordeaux varietals, along with the same yeast rehydration and nutrient protocols as for the Chardonnay. For the MLF, here too I will use Lactoenos B7 (LF16) Direct inoculum, and also inoculate shortly after the AF has started to get the MLF to complete at the same time as the AF or shortly thereafter.

2018 Willamette Valley Pinot Noir, Chehalem Mountains AVA

The numbers for this Pinot look very, very good. May this be the greatest Pinot that this Pinot lover ever dreamed about? The pH is in the perfect range with a low K+ level. TA too is perfect, which will increase during the AF while the impact from the MLF will be relatively small given that the TA is predominantly tartaric acid.

YAN should be around the 250 mg/L here too for this Brix level, so I will make up the difference by adding some DAP (Thiazote PH).

The same analysis as for the Cab for SO2, DO, IC, hue and brilliance of red apply here. IC is quite a bit lower, but that is expected for a Pinot, which always requires extra focus and effort on color extraction and stabilization due to low anthocyanin content in grape skins. Note, however, that the brilliance of red (28.6%) is higher than for the Cab, so that’s good because it means that the yellow component is lower. I’m expecting to still get a fairly deep, rich red color by implementing the same enzymatic, color and tannin addition protocols as for the Cab.

My choice of yeast for this wine is Lalvin RC-212, which is recommended for rich, full-bodied Pinot Noir, along with the same yeast rehydration and nutrient protocols as for the Chardonnay.

For the MLF, here too I will use Lactoenos B7 (LF16) Direct inoculum, and also inoculate shortly after the AF has started to get the MLF to complete at the same time as the AF or shortly thereafter.

Ready to be Making Some Serious Wines

I’m excited. Things look good, so it’s time to inoculate and start fermentation.

I will report back at the conclusion of the AF and MLF and pressing (reds) to see how things progressed along with a similar analysis of the same parameters as above. I will also start monitoring Total Phenols (TP) to gauge polyphenol content and what it all means.

So stay tuned, we’ve got some great wines in the making!

Cheers,

Daniel